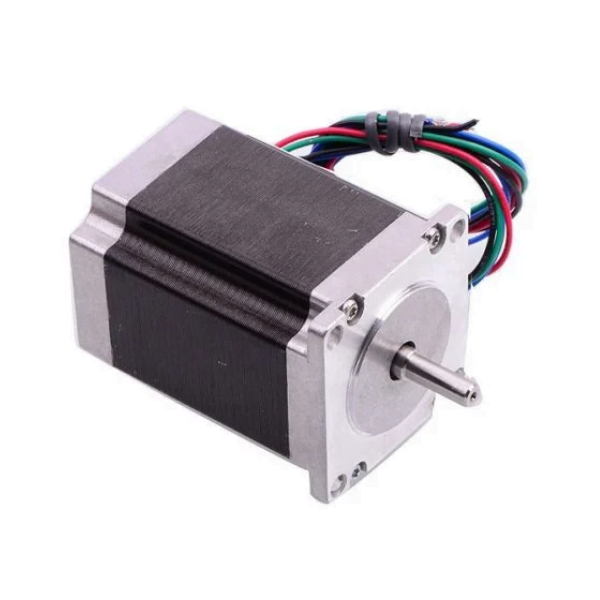

Description

The stepper motors move in precisely repeatable steps, hence they are the motors of choice for the machines requiring precise position control. The NEMA 23 18.9 kg-cm Hybrid Stepper Motor provides excellent response to starting, stopping and reversing pulses from stepper motor driver.

One can equip them on CNC Milling, CNC Router like application which demands extra torque than provided by NEMA17 Stepper Motors.

It is a brushless DC motor, so the life of this motor is dependent upon life of the bearings. The position control is achieved by a simple Open Loop control mechanism so doesn’t require complex electronic control circuitry.

The motor’s shaft has been machined for good grip with a pulley, drive gear etc. and especially avoiding stall or slip.

Note :

- The NEMA 23 18.9 kg-cm Hybrid Stepper Motor dimensions and weight may have ±2% error.

- Resonances can occur because of improper instalment.

- Not easy to operate at extremely high speeds.

Features :

- Comparably more powerful than NEMA17 motors.

- Input pulse decides the rotation angle of the motor.

- High accuracy of around 3 to 5% a step.

- Provides good starting, stopping and reversing.

- Control of this motor is less costly because of exclusion of complex control circuitry.

- The speed is proportional to the frequency of the input pulses.

Specifications:

| Step Angle | 1.8° |

| Holding Torque (Kg-Cm) | 18.9 |

| Operating Voltage (VDC) | 3.2 |

| Supply Current (A) | 2.8 A/Phase |

| No. of Leads | 4 |

| Inductance (mH/Phase) | 3.6 |

| Resistance (Ω) | 1.13 |

| Rotor Inertia (gm-cm2) | 480 |

| Weight (gm) | 1020 |

| Dimensions (mm) LxWxH | 76x57x57 |

| Frame Size (mm) | 57 x 57 |

| Inductance Accuracy | ±20% |

| Resistance Accuracy | ±10% |

| Shaft Diameter (mm) | 6.35 |

| Shaft Length (mm) | 20.6 |

| Step Angle Accuracy | ±5% |

| Cable Length (cm) | 30 |

| Shipment Weight | 1.2 kg |

*Product images are shown for illustrative purposes only and may differ from actual product.